COMPLETED PROJECTS

Turnkey Solutions

Pressure Vessels, Tanks and Equipment

PRECAUTIONARY MEASURES – FOR TANKS, MIXTURES & AGITATORS

- All Qualified Weldors To Be Used For Tank Fabrication Duly Qualified Through Wps, Pqr & Wpq – Welding Procedure As Per Asme Section Ix.

- Pmi To Be Done Before Dispatch For Double Confirmation Of Finished Goods To Client. In Addition To Mtc & Lab Report Verification Through Mir & Mrir.

- Extra Precaution Of Mill Finish Material From Scratches During Fabrication, We Will Use Pvc Coated Material.

- Dp To Be Done To Ensure The Crack Free Welding.

- Radiography To Be Done On Welded Portion To Avoid The Defective Welding Quality.

- Hydro Test To Be Done To Check Any Kind Of Leakage.

- Welded Portion To Be Band Polished For Welding Identification And Free From Black Marks.

Civil & Structure

Process and Utility Piping

PRECAUTIONARY MEASURES – FOR PROCESS & UTILITY PIPING SYSTEM

- All Qualified Weldors To Be Used For Piping System Duly Qualified Through Wps, Pqr & Wpq – Welding Procedure As Per Asme Section 31.3 .

- Pmi To Be Done Before Dispatch Pre Fabricated Process Piping And Raw Material Of Utility Piping, Double Confirmation Of Finished Goods To Client. In Addition To Mtc & Lab Report Verification Through Imir.

- We Are Purchasing Process Piping Like Ss-316 Tubing And Fitting And Pfa Tubing With Fitting Duly Fda Approved, Which Is Additional Features In Our Procurement Quality Point Of View (High Quality Standard).

- Dp To Be Done To Ensure The Crack Free Welding.

- Hydro Test To Be Done To Check Any Kind Of Leakage.

- Radiography To Be Done On Welded Portion To Avoid The Defective Welding Quality.

- Welded Portion To Be Band Polished For Welding Identification And Free From Black Marks.

HVAC

Electrical

Instrumentation

Insulation

Mane India Private Limited

PROJECT DEATILS

- Project: Flavour and Fragrance

- Approximate Cost in Crores: 25 Crores

- Delivery to Commissioning period: from November 2019 to December 2020

Merino Industries Limited

PROJECT DEATILS

- Project : Plant of Engineered Ply

- Approximate Cost in Crores : 45 Crores

- Delivery to Commissioning period : from April 2022 to August 2023

Alkyl Amines Chemicals Limited

PROJECT DEATILS

- Project : Manufacturing of Storage Tan, Pressure Vessel etc for Various Project

- Approximate Cost in Crores : 15 Crores

- Delivery to Commissioning period : Continuous

Durr India Private Limited

PROJECT DEATILS

- Project : Equipment for Paint Shop for Various Project

- Approximate Cost in Crores : 40 Crores

- Delivery to Commissioning period : Continuous

Hindalco Industries Limited

PROJECT DEATILS

- Project : Bio-mass

- Approximate Cost in Crores : 6 Crores

- Delivery to Commissioning period : June 2021 to June 2022

Hindalco Industries Limited

PROJECT DEATILS

- Project : Varun

- Approximate Cost in Crores : 42 Crores

- Delivery to Commissioning period : June 2023 (Work in Progress)

MARS International India Private Limited

PROJECT DEATILS

- Project : Galaxy

- Approximate Cost in Crores : 25 Crores

- Delivery to Commissioning period : August 2020 to March 2022

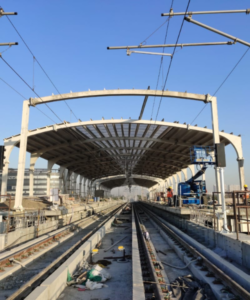

Pune Maha Metro

PROJECT DEATILS

- Project : Elevated Metro Station

- Approximate Cost in Crores : 15 Crores

- Delivery to Commissioning period : August 2020 to November 2021

Thermax Onsite Energy Solutions Limited

PROJECT DEATILS

- Project : Biocon Limited

- Approximate Cost in Crores : 6 Crores

- Delivery to Commissioning period : April 2022 to March 2023

Toyo Ink India Private Limited

PROJECT DEATILS

- Project : PU and Hardner Plant

- Approximate Cost in Crores : 5 Crores

- Delivery to Commissioning period : December 2020 to November 2021